Plastic production begins with the extraction of raw material from earth, such as oils, natural gas, coal, and crude oil. Though plastic mainly derived from fossil, it can also be produced from renewable sources, such as plants, algae or bacteria. These are called bioplastics, unlike plastic from fossil fuels, bioplastic is biodegradable or compostable within 12-24 months (if not ended up in the ocean or landfill), but unfortunately, plastic from renewable sources have some drawbacks, such as expensive production and lower performance.

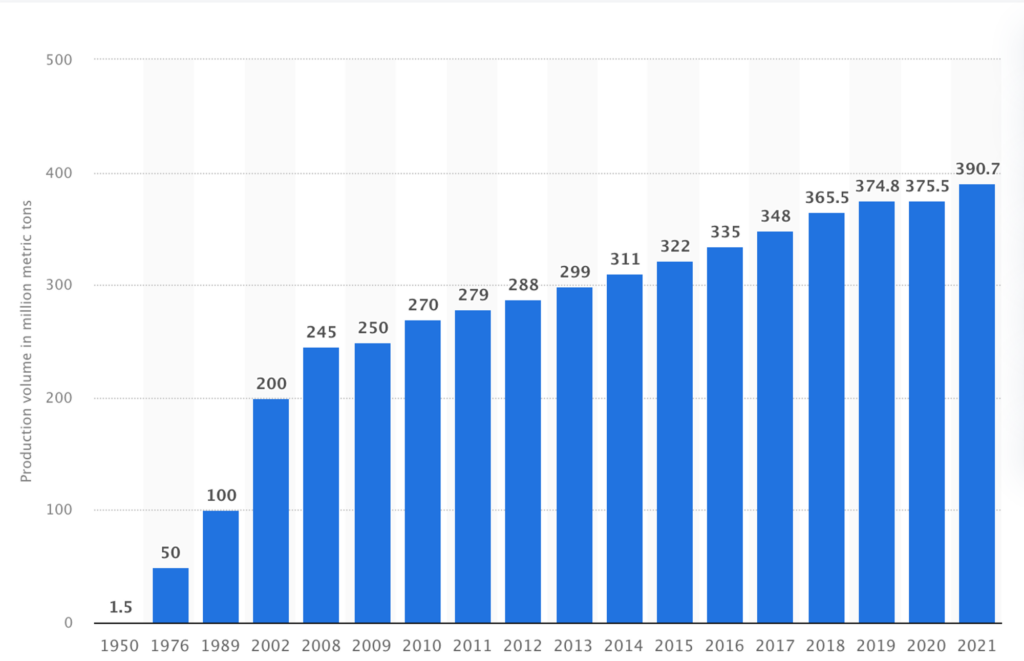

Surprisingly, the production of plastic in the last ten years is exceeding the whole plastic production in the last century. In 2012, Asia accounted for about 51% of the global plastic production, followed by Europe with 18%, North America with 17%, and the rest of the world with 14%. The global plastics production was estimated at 390 million metric tons in 2021, yet bioplastic represents less than 1% of the total.

The whole lifecycle of plastic is producing carbon dioxide, from the drilling, production, and disposal or incineration. However, the drilling process contribute the most to its carbon footprint, accounted for 96% of its lifecycle. In 2019, plastic emits 1.8 tonnes of greenhouse gas emissions, this does not include the production of the plastic, which is estimated to be much higher

Plastic nowadays is derived from hydrocarbons as raw material. These hydrocarbons are sourced from fossil fuels, such as crude oil and natural gas. Fossil fuels are commonly used as material because they are abundant, cost-effective and they also have a high energy content, which makes them more suitable. There are also bio-based hydrocarbons – as for alternatives – which are derived from plants and algae, but they don’t contain as much energy per unit compared to hydrocarbons that come from fossil fuels. It’s not also very reliable as their availability relies on the availability of suitable feedstocks.

Hydrocarbons are extracted from a drilling process, which releases carbon dioxide in the process. This mainly happens from the combustion of fossil fuels for power generation which is typically powered by diesel generators or natural gass. These engines burn fossil fuels, releasing CO2 into the atmosphere. The drilling process requires a lot of energy, though it can vary depending on the technology being used and geological conditions, drilling a single foot (one-foot-deep) can be roughly equivalent to the energy used by an average US household in a day, including heating, cooking, cooling, and appliances (around 20-30 KWh).

The other process of drilling that also contributes to CO2 emission are venting and flaring. During drilling, natural gas is often released from the reservoir directly into the atmosphere, this process is called venting. This process is sometimes done for safety reasons, such as relieving pressure in equipment to prevent potential explosion. When venting is not safe or practical, flaring becomes an alternative, which the excess waste gasses burn off. Flaring turns gasses into less harmful substances like carbon dioxide and water vapor, while venting releases methane, which is more potent than CO2, nevertheless, it is still harmful.

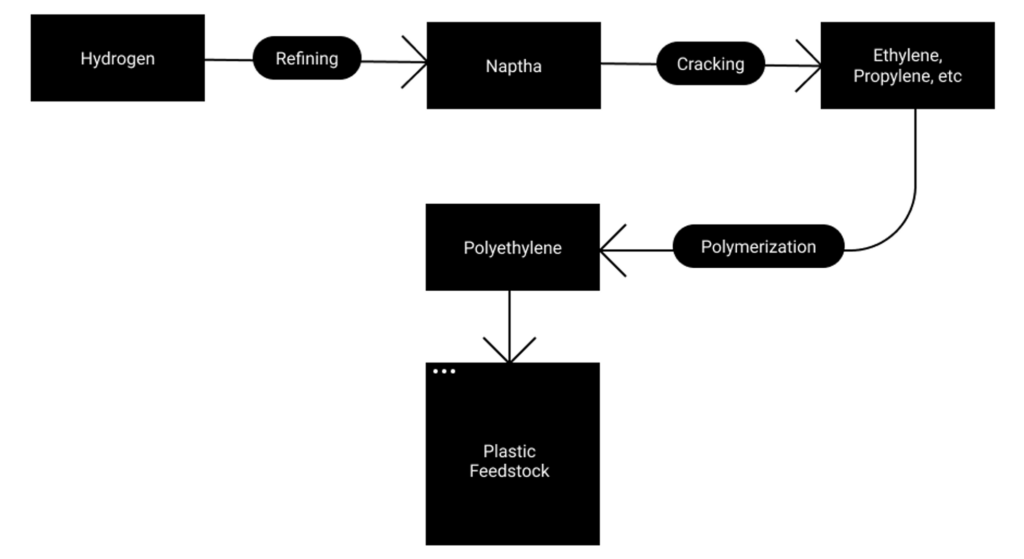

Drilling is not the only process accounted for releasing greenhouse gasses, crude oil extracted from drilling then has to undergo processes which also emit carbon dioxide. Hydrocarbon is the primary ingredient to produce plastic, but hydrocarbon from crude oils is actually a complex mixture of hydrocarbon which is not suitable for producing specific types of plastics, some processes are required to transform crude oil into desired feedstocks for plastic production. First of all, crude oil has to undergo a distillation process to separate into its various components The process is also called Refining. Refining is an energy-intensive process, that requires heat at around 200-400 C, the end product of this product is a hydrocarbon compound like naphtha. Naptha still has to be broken down into smaller hydrocarbons which can be done through heating (again… ), but this time it requires higher temperatures, ranging from 500 to 900 c. This process will convert heavier hydrocarbons into lighter hydrocarbons, such as ethylene or propylene. This whole process is called Cracking.

The last step before the smaller molecules of hydrocarbon – called monomers – can become feedstock for plastic, they have to form into long chains of polymers. The process is called Polymerization. The process involves a combination of monomers through a chemical process that occurs at elevated temperature and pressure to facilitate chemical bounding.

Refining and Cracking are both energy-intensive process that rely on heat, often generated by burning fossil fuels. The combustion of these fuels releases the ehat necessary of the process, contributing to the emission of CO2 and other greenhouse gases into the atmosphere.

References

- What is The Process of Plastic Production? | Rayda Plastics

- The future of plastics – Curious (science.org.au)

- https://www.bpf.co.uk/plastipedia/how-is-plastic-made.aspx